Axial Compressors

Axial compressors are typically designed numerically since the flows in them are highly complex and three dimensional. The compression produced by the stage is determined by the tangential Mach number. The flow through the compressor depends on the axial Mach number and the area of the annulus. Improvements in design of the blades have allowed relative Mach numbers of 1.5 being achieved at the tip of the fan. The hub may be half the tip radius of the blades and the tangential velocity can vary by a factor of 2. Blades which operate supersonically for part of their span are called transonic.

Solidity is the ratio of the chord of the blades to the tangential distance subtended by the blade. Aspect ratio relates the blade chord to the blade length. The modern trend is towards lower aspect ratios. Higher aspect ratio blades tend to be lighter and blade loss is slightly less catastrophic an event. They often have part span shrouds to prevent flutter. Wide chord blades have recently been engineered to provide better performance, since they allow higher pressure ratios to be achieved. The width of the blade allows for a better shock structure in the supersonic regions of the blade, and a lower pressure gradient that delays separation. They can also avoid part span shrouds since their torsional rigidity is higher.

The blades act like staggered airfoils and they can tolerate a few degrees of incidence before the loss factor diverges. The loss factor is defined as the loss in total pressure divided by the dynamic pressure of the incident flow (pt-p). The minimum loss factor ranges from about 0.02 increasing with the inlet Mach number.

The compressor blade rows perform diffusion in reducing the velocity difference while increasing pressure.

Blade profiles

The earliest compressors employed circular arc blades. Double circular arcs have also been used, while modern compressors use more sophisticated 3D CFD designed blades.

Subsonic blades

For subsonic blades the passage widens as the air goes through it and simultaneously turns. The blades have higher inclination on the leading edge relative to the axial direction which reduces at the trailing edge resulting in a widening channel through which air must flow. The convex (surface) surface presents a large adverse pressure gradient which tends to enlarge the boundary layer. If the adverse gradient exceeds a critical level then flow separation and blade stalling occurs.

Aspirated compressor blades evacuate the suction side boundary layer and allow for larger diffusion.

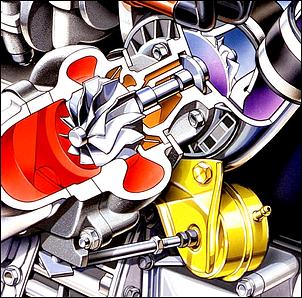

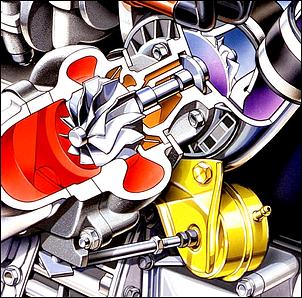

Transonic blades

Fan blades are typically transonic. The incident flow approached the blade at supersonic velocity. The initial diffusion happens through a converging wedge shaped passage that creates multiple inclined shocks terminated by a stronger normal shock in the passage that makes the flow subsonic. The subsonic flow is then further diffused by a diverging passage as in subsonic blades.

Supersonic blading is easy to see in the outer periphery of the fans of commercial airliners. The leading edges are sharp and appear to be curved slightly in the opposite direction to create the supersonic wedge. The incident flow while highly 3 dimensional is qualitatively comparable to the flow into a 2D intake of a supersonic aircraft such as the F-15.

For compressor stages it is advantageous to bring the flow subsonic by the use of variable stators. Most large modern engines have variable stators that allow subsonic blading to be used while providing good performance throughout the operational envelope. The variable stator adds swirl to the flow so that the Mach number variation between root and tip is reduced preventing stall at the root of the blades.

Multistage compressors

For multiple compressor stages on a shaft the inlet Mach number progressively drops as the air is compressed and heats up.

Mass flow

The mass flow in a duct is maximum if the Mach number is close to unity. The axial Mach number through the engine is kept close to one to reduce the blade heights. The blockage introduced by the hub and casing boundary layers, as well as the cross sectional area of the blades reduces the mass flow below the theoretical value. Actual axial Mach numbers range up to 0.6.

Loss mechanisms

Real compressors suffer from various loss mechanisms.

Tip leakage

Hub and casing boundary layers

Seal leakages

TBD

Stage performance

The corrected speed of the engine is defined as

Corrected speed

Off design behavior

A multistage compressor operating at speeds lower than designed or with lower pressure ratio than designed, will load the front stages more than the rear stages. This can result in stalling of the front stages. Variable stators and multiple shafts can be sued to solve this. Most modern turbofans have multiple shafts as well as variable stators in the front compressor stages. The variable stators balance the compression between the front and rear stages at off design conditions.

Matching

The compressor and turbine flows are “matched” to provide sufficient flow through the turbine, as well as sufficient power at the right rpm for the compressor. The temperature increase in the combustor allows us to calculate the relative areas required Transients

Surge

To accelerate and engine the fuel added in the combustor is increased. This increases the temperature and the pressure in the combustor which now has to be generated by the compressor. If the compressor is too close to stall a surge may happen where the compressor stalls. In extreme cases the flow is reversed through the compressor and the hot combustor gases exit the front of the compressor. The cycle then continues at the Helmholtz frequency of the system till the disturbance is damped out. The engine controller is tasked with ensuring that the compressor doesn’t reach the surge line during acceleration.

In deceleration the fuel quantity is decreased and if the flame becomes too lean a flameout may occur.

Rotating stall

Unsteady flows in the compressor may cause some sections to stall (stall cells). These rotate with the blades and propagate from blade to blade, possibly exciting vibrations that can cause damage. The rotating stall precedes a full scale surge in which the compressor stalls in the entire circumference.

Axial compressors are typically designed numerically since the flows in them are highly complex and three dimensional. The compression produced by the stage is determined by the tangential Mach number. The flow through the compressor depends on the axial Mach number and the area of the annulus. Improvements in design of the blades have allowed relative Mach numbers of 1.5 being achieved at the tip of the fan. The hub may be half the tip radius of the blades and the tangential velocity can vary by a factor of 2. Blades which operate supersonically for part of their span are called transonic.

Solidity is the ratio of the chord of the blades to the tangential distance subtended by the blade. Aspect ratio relates the blade chord to the blade length. The modern trend is towards lower aspect ratios. Higher aspect ratio blades tend to be lighter and blade loss is slightly less catastrophic an event. They often have part span shrouds to prevent flutter. Wide chord blades have recently been engineered to provide better performance, since they allow higher pressure ratios to be achieved. The width of the blade allows for a better shock structure in the supersonic regions of the blade, and a lower pressure gradient that delays separation. They can also avoid part span shrouds since their torsional rigidity is higher.

The blades act like staggered airfoils and they can tolerate a few degrees of incidence before the loss factor diverges. The loss factor is defined as the loss in total pressure divided by the dynamic pressure of the incident flow (pt-p). The minimum loss factor ranges from about 0.02 increasing with the inlet Mach number.

The compressor blade rows perform diffusion in reducing the velocity difference while increasing pressure.

Blade profiles

The earliest compressors employed circular arc blades. Double circular arcs have also been used, while modern compressors use more sophisticated 3D CFD designed blades.

Subsonic blades

For subsonic blades the passage widens as the air goes through it and simultaneously turns. The blades have higher inclination on the leading edge relative to the axial direction which reduces at the trailing edge resulting in a widening channel through which air must flow. The convex (surface) surface presents a large adverse pressure gradient which tends to enlarge the boundary layer. If the adverse gradient exceeds a critical level then flow separation and blade stalling occurs.

Aspirated compressor blades evacuate the suction side boundary layer and allow for larger diffusion.

Transonic blades

Fan blades are typically transonic. The incident flow approached the blade at supersonic velocity. The initial diffusion happens through a converging wedge shaped passage that creates multiple inclined shocks terminated by a stronger normal shock in the passage that makes the flow subsonic. The subsonic flow is then further diffused by a diverging passage as in subsonic blades.

Supersonic blading is easy to see in the outer periphery of the fans of commercial airliners. The leading edges are sharp and appear to be curved slightly in the opposite direction to create the supersonic wedge. The incident flow while highly 3 dimensional is qualitatively comparable to the flow into a 2D intake of a supersonic aircraft such as the F-15.

For compressor stages it is advantageous to bring the flow subsonic by the use of variable stators. Most large modern engines have variable stators that allow subsonic blading to be used while providing good performance throughout the operational envelope. The variable stator adds swirl to the flow so that the Mach number variation between root and tip is reduced preventing stall at the root of the blades.

Multistage compressors

For multiple compressor stages on a shaft the inlet Mach number progressively drops as the air is compressed and heats up.

Mass flow

The mass flow in a duct is maximum if the Mach number is close to unity. The axial Mach number through the engine is kept close to one to reduce the blade heights. The blockage introduced by the hub and casing boundary layers, as well as the cross sectional area of the blades reduces the mass flow below the theoretical value. Actual axial Mach numbers range up to 0.6.

Loss mechanisms

Real compressors suffer from various loss mechanisms.

Tip leakage

Hub and casing boundary layers

Seal leakages

TBD

Stage performance

The corrected speed of the engine is defined as

Corrected speed

Off design behavior

A multistage compressor operating at speeds lower than designed or with lower pressure ratio than designed, will load the front stages more than the rear stages. This can result in stalling of the front stages. Variable stators and multiple shafts can be sued to solve this. Most modern turbofans have multiple shafts as well as variable stators in the front compressor stages. The variable stators balance the compression between the front and rear stages at off design conditions.

Matching

The compressor and turbine flows are “matched” to provide sufficient flow through the turbine, as well as sufficient power at the right rpm for the compressor. The temperature increase in the combustor allows us to calculate the relative areas required Transients

Surge

To accelerate and engine the fuel added in the combustor is increased. This increases the temperature and the pressure in the combustor which now has to be generated by the compressor. If the compressor is too close to stall a surge may happen where the compressor stalls. In extreme cases the flow is reversed through the compressor and the hot combustor gases exit the front of the compressor. The cycle then continues at the Helmholtz frequency of the system till the disturbance is damped out. The engine controller is tasked with ensuring that the compressor doesn’t reach the surge line during acceleration.

In deceleration the fuel quantity is decreased and if the flame becomes too lean a flameout may occur.

Rotating stall

Unsteady flows in the compressor may cause some sections to stall (stall cells). These rotate with the blades and propagate from blade to blade, possibly exciting vibrations that can cause damage. The rotating stall precedes a full scale surge in which the compressor stalls in the entire circumference.